NEWSNEWS

Featured products

Contact Us

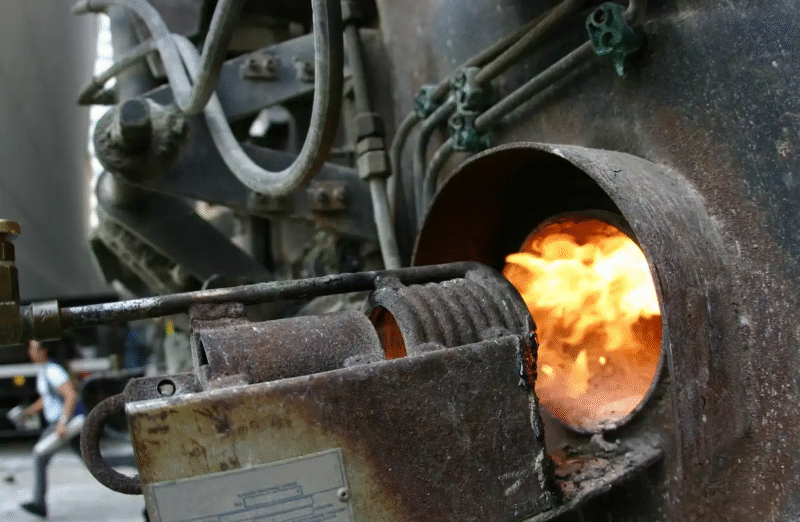

Tempering

2018-09-091. What is tempering?

Tempering is a heat treatment process that heats the quenched metal material or parts to a certain temperature, keeps them warm for a certain period of time, and then cools them in a certain way. Tempering is an operation that follows quenching and is usually the last step in the heat treatment of the workpiece. Therefore, the combined process of quenching and tempering is called final treatment.

2. The main purposes of quenching and tempering are:

1) Reduce internal stress and reduce brittleness. Quenched parts have great stress and brittleness. If they are not tempered in time, they will often deform or even crack.

2) Adjust the mechanical properties of the workpiece. After quenching, the workpiece has high hardness and high brittleness. In order to meet the different performance requirements of various workpieces, tempering can be used to adjust the hardness, strength, plasticity and toughness.

3) Stabilize the size of the workpiece. Tempering can stabilize the metallographic structure to ensure that no deformation occurs during subsequent use.

4) Improve the cutting performance of certain alloy steels.

3. The role of tempering is:

① Improve the stability of the organization, so that the workpiece will no longer undergo organizational transformation during use, so that the geometric dimensions and performance of the workpiece remain stable.

② Eliminate internal stress to improve the performance of the workpiece and stabilize the geometric dimensions of the workpiece.

③ Adjust the mechanical properties of steel to meet the use requirements.

The reason why tempering has these effects is that when the temperature rises, the atomic activity is enhanced, and the atoms of iron, carbon and other alloy elements in steel can diffuse faster, realizing the rearrangement of atoms, so that the unstable unbalanced organization is gradually transformed into a stable balanced organization. The elimination of internal stress is also related to the decrease in metal strength when the temperature rises. Generally, when steel is tempered, the hardness and strength decrease, and the plasticity increases. The higher the tempering temperature, the greater the change in these mechanical properties. Some alloy steels with a high content of alloying elements will precipitate some fine metal compounds when tempered in a certain temperature range, which increases the strength and hardness. This phenomenon is called secondary hardening.

Tempering requirements: Workpieces with different uses should be tempered at different temperatures to meet the requirements in use.

① Cutting tools, bearings, carburized and quenched parts, and surface quenched parts are usually tempered at low temperatures below 250°C. After low-temperature tempering, the hardness does not change much, the internal stress is reduced, and the toughness is slightly improved.

② Springs are tempered at medium temperatures at 350-500°C to obtain higher elasticity and necessary toughness.

③ Parts made of medium-carbon structural steel are usually tempered at high temperatures at 500-600°C to obtain a good combination of suitable strength and toughness.

When steel is tempered at around 300°C, its brittleness often increases. This phenomenon is called the first type of temper brittleness. Generally, tempering should not be done in this temperature range. Some medium-carbon alloy structural steels are also prone to brittleness if they are slowly cooled to room temperature after high-temperature tempering. This phenomenon is called the second type of temper brittleness. Adding molybdenum to the steel, or cooling it in oil or water during tempering, can prevent the second type of temper brittleness. Reheating the second type of temper brittle steel to the original tempering temperature can eliminate this brittleness.

In production, it is often based on the requirements for workpiece performance. According to the different heating temperatures, tempering is divided into low-temperature tempering, medium-temperature tempering, and high-temperature tempering. The heat treatment process combining quenching and subsequent high-temperature tempering is called quenching and tempering, that is, it has high strength and good plasticity and toughness.

1) Low-temperature tempering: 150-250℃, M tempering, reducing internal stress and brittleness, improving plasticity and toughness, with high hardness and wear resistance. Used to make measuring tools, cutting tools and rolling bearings, etc.

2) Medium-temperature tempering: 350-500℃, T tempering, with high elasticity, certain plasticity and hardness. Used to make springs, forging dies, etc.

3) High-temperature tempering: 500-650℃, S tempering, with good comprehensive mechanical properties. Used to make gears, crankshafts, etc.