PRODUCTSSTAINLESS-STEEL-CONVEYOR-BELT

Featured products

Contact Us

Direct Edge Welding – Provides maximum structural integrity and durability

U-Shaped Edge Reinforcement

Prevents material spillage and enhances belt stability

Hook Edge Process

Provides secure tracking and prevents edge unraveling

Special Customization

Tailored solutions for unique industrial requirements

Product Description

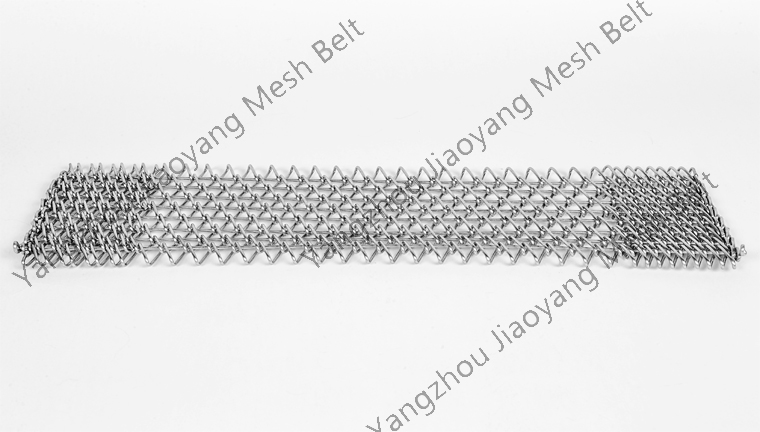

The Balanced Weave Conveyor Belt (also known as Universal Weave Conveyor Belt) features a dual-spiral structure with left and right spiral wires tightly interlocked by curled cross wires. These components are precision-welded, creating an exceptionally stable and durable mesh structure.

Mesh Pattern: Uniform rectangular or diamond-shaped openings for consistent airflow and material support.

Edge Reinforcement: Welded or bent edges prevent deformation and enhance operational stability.

Material Options

Stainless Steel 304 – General-purpose corrosion resistance.

Stainless Steel 316L – Superior acid/alkali resistance.

Stainless Steel 310S – Extreme heat resistance (up to +1250℃).

Key Applications

✔ High-Temperature Environments: Sintering furnaces, brazing furnaces, metal smelting.

✔ Heat-Resistant Transport: Ideal for hot products, glass processing, and ceramic industries.

✔ Stable Performance: Maintains integrity under continuous thermal stress.