PRODUCTSSTAINLESS-STEEL-CONVEYOR-BELT

Featured products

Contact Us

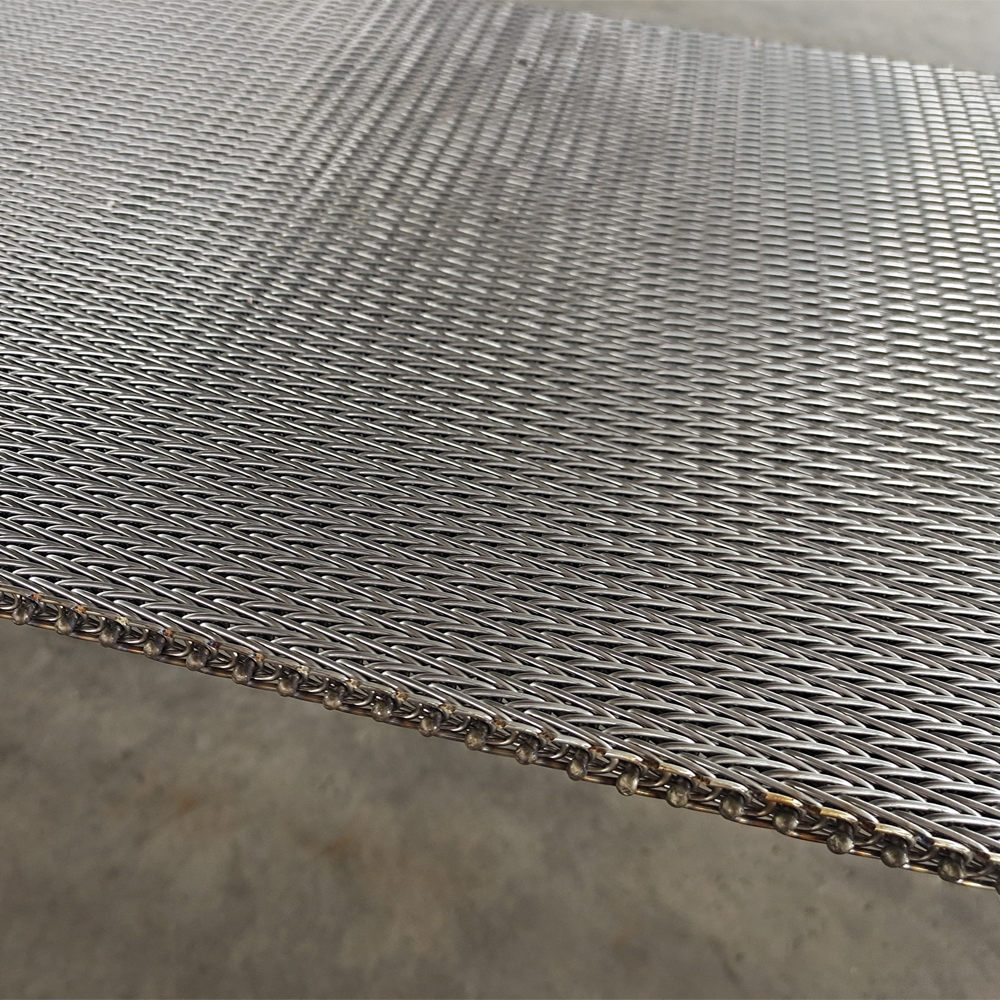

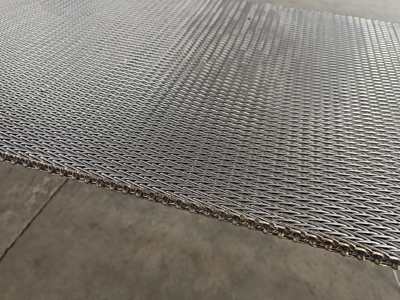

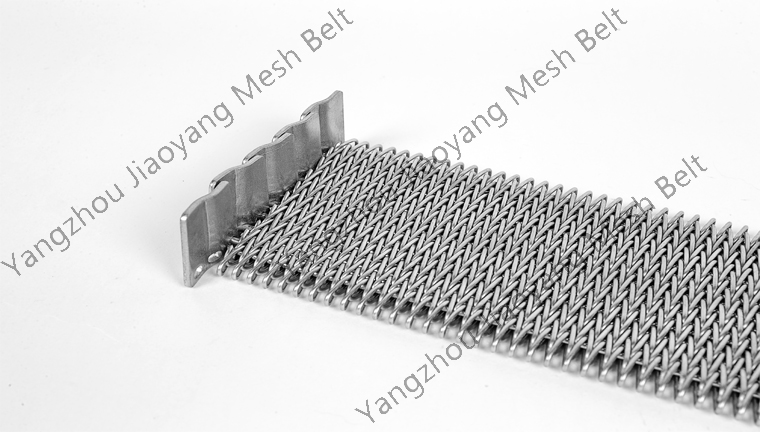

- chevron conveyor belt with welded edge

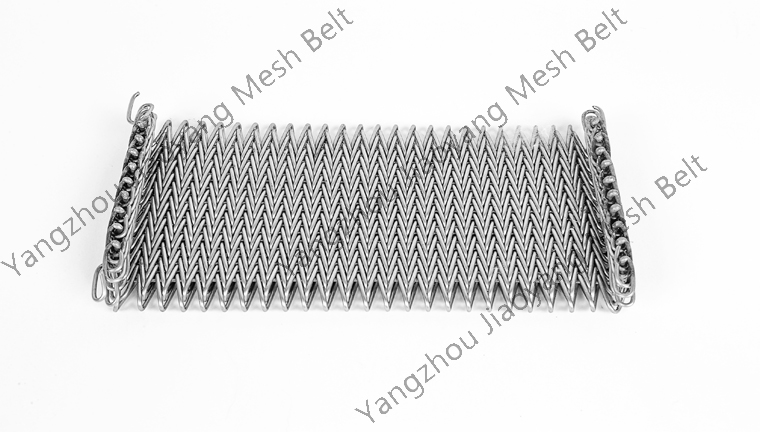

- Compound weave mesh belt with welded edge

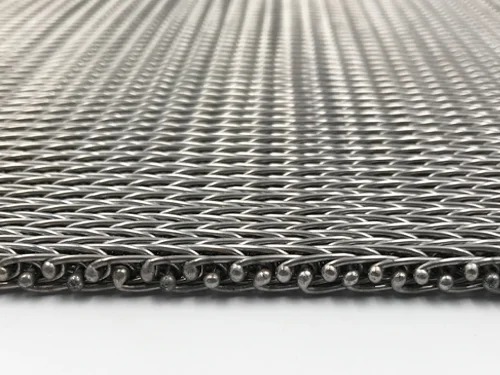

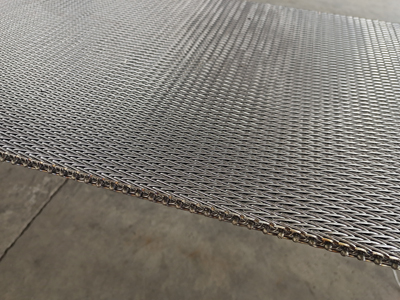

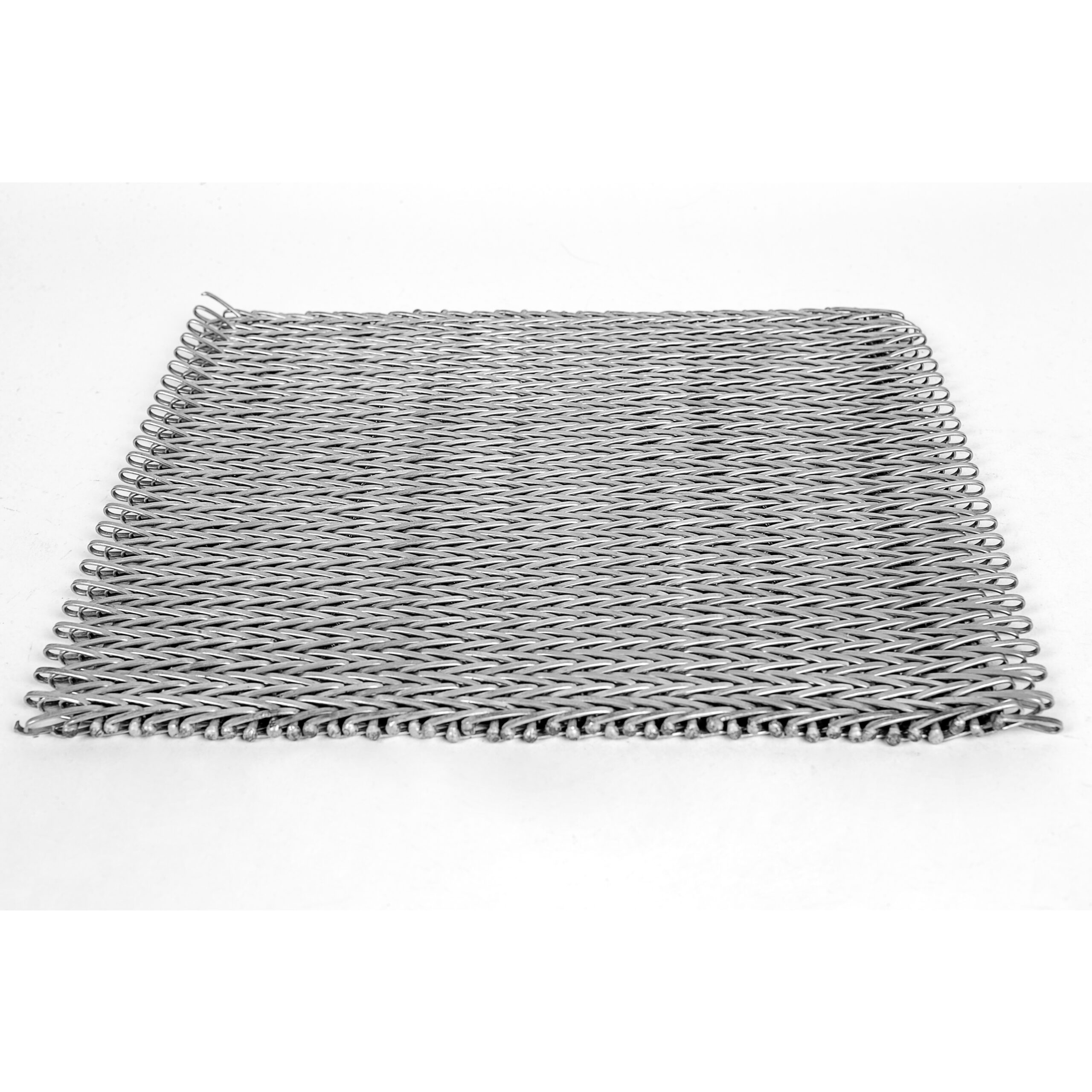

Compound Balanced Weave Belts with Welded Edge.The standard available type of edge finish for this application is welding, facilitated by the close meshing of both the crimp and cross wire.

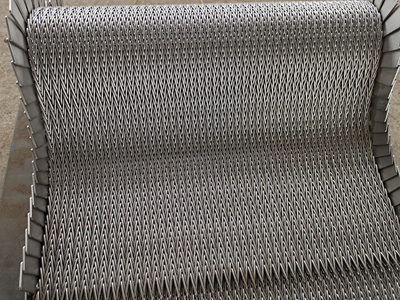

Compound Balanced Weave Conveyor Belt, Also Named Cordweave Conveyor Belt, Compound Balanced Woven Belt Or V-Shaped Conveyor Belt, Have Right-Hand And Left-Hand Spirals Interconnecting By Straight Cross Rods.

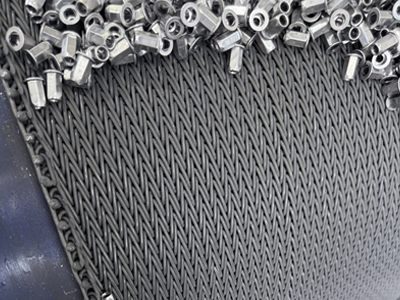

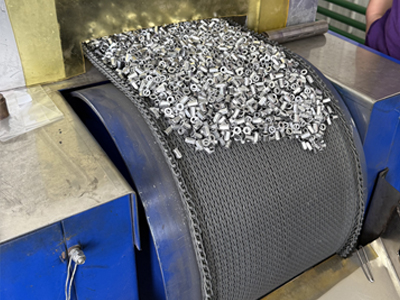

Compound Belt Is Essentially A Balanced Spiral Belt That Has Multiple Spirals And Cross Rods Per Pitch. This Compound Structure Closes Up The Apertures Within The Belt, Giving Compound Weave Its Characteristic High Density And Flat Surface. It Is Similar To A Balanced Weave Besides Smaller Opening And Far Denser Weave. As A Result Of This Construction, Compound Weave Conveyor Belts Offer An Extremely Close And Flat Mesh For Applications Where Very Small Items Are Being Conveyed. Compound Weave Also Provides A Uniform Heat Transfer Across The Belt Due To Its High Density And Smooth Carrying Surface. These Characteristics Make Compound Weave A Popular Choice In A Wide Variety Of Applications, Ranging From Biscuit Baking To Sorting Small Mechanical Components.

Materials and A pplications

Generally, the material used to make the Compound Weave Conveyor Belts is stainless steel or high carbon steel.

Compound weave conveyor belts made from 304 and 316 stainless steel are typically used in the food industry due to their hygienic properties, while those made from 310S and 314 stainless steel are preferred in the heat treatment industry for their high temperature and oxidation resistance.

310S and 314 stainless steel wire offer high temperature resistance, strong oxidation resistance, and excellent mechanical properties. These features make mesh conveyor belts made from 310S and 314 stainless steel ideal for addressing high temperature issues in powder metallurgy furnaces. These belts resist short cycles, peeling, and fractures, and can withstand temperatures up to 1000-1250°C.

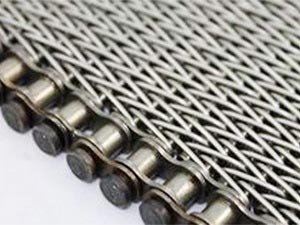

Driving Methods

The belt can be driven by friction rollers or chains. In some cases, products need to be upgraded or separated, and we can also provide cross flights and side plates according to user needs.

Features of Compound Weave Conveyor Belt

- Small open area. The compound weave conveyor belt has a little open area, which is suitable to conveyor the small items.

- Use multiple environments. High resistance against acid, alkaline, chemical, abrasion, and corrosion.

- High tensile strength. The compound weave conveyor belt has multiple spirals and cross rods on each pitch, so it can supply higher tensile strength than other types of conveyor belt.

- High-temperature resistance. The compound weave conveyor belt is made of high-quality materials, including stainless steel and nickel alloy steel, which have excellent temperature resistance performance.

- Durable and long service life. The unique structure and high-quality material can ensure the long service life of compound conveyor belt.

- Uniform heating. Provides uniform heat transfer across the belt.

- Baffles can be added. Different types of baffles can be added at the both side and center of conveyor belt for sorting and conveying products.

Edge Type

compound weave conveyor belt, we can provide different edge structures to meet different applications.

Application scenarios

● Heat treatment industry: quenching furnace, normalizing furnace, tempering furnace, bright annealing furnace, cleaning elevator, etc.

● Glass manufacturing industry: glass annealing furnace, tempering furnace, etc.

● Electronics industry: electronic component sintering furnace, curing furnace, etc.

● Ceramic industry: ceramic sintering furnace, drying furnace, etc.

Material Availability

The compound weave conveyor belt is made of stainless steel and high carbon steel. They all have excellent high temperature resistance performance and high tensile strength. All these can ensure the compound weave conveyor belt be a strong, durable and high lifespan products.

| Material | Maximum Wire Operating Temperature °C |

| Carbon Steel | 550 °C |

| 304 Stainless Steel | 750 °C |

| 316 Stainless Steel | 800 °C |

| 316L Stainless Steel | 800 °C |

| 314 Stainless Steel | 1200 °C |

| 310S Stainless Steel | 1200 °C |

| Cr20Ni80 | 1200 °C |

| If you have other material requirements, please contact us. | |

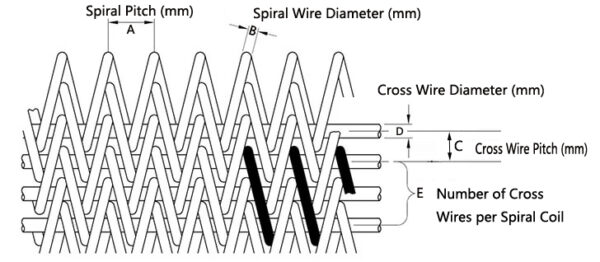

Common Specifications of Compound Balanced Weave Belts

| Specification Item | A: Spiral Pitch (mm) | C: Cross Wire Pitch (mm) | D: Cross Wire Diameter (mm) | B: Spiral Wire Diameter (mm) | E: Number of Cross Wires per Spiral Coil |

| CB3-5.08-3.05-1.22-1.22 | 5.08 | 3.05 | 1.22 | 1.22 | 3 |

| CB4-11.7-6.5-3.0-2.6 | 11.7 | 6.5 | 3.0 | 2.6 | 4 |

| CB4-10.5-5.7-2.6-2.3 | 10.5 | 5.7 | 2.6 | 2.3 | 4 |

| CB4-9.0-5.0-2.3-2.0 | 9.0 | 5.0 | 2.3 | 2.0 | 4 |

| CB4-7.2-4.0-1.8-1.6 | 7.2 | 4.0 | 1.8 | 1.6 | 4 |

| CB4-6.5-3.8-1.8-1.4 | 6.5 | 3.8 | 1.8 | 1.4 | 4 |

| CB4-5.5-2.8-1.4-1.2 | 5.5 | 2.8 | 1.4 | 1.2 | 4 |

| CB4-4.5-2.3-1.2-1.0 | 4.5 | 2.3 | 1.2 | 1.0 | 4 |

| CB4-3.7-2.1-1.2-0.8 | 3.7 | 2.1 | 1.2 | 0.8 | 4 |

| CB5-8.71-3.39-1.63-1.3*1.3 | 8.71 | 3.39 | 1.63 | 1.3*1.3 | 5 |

Note:

If Flat Wire, Please Give Us Cross Section.Custom specifications available upon request. |

|||||

Compound balance weave belts offer several advantages, making them suitable for various industrial applications. Here are some key advantages of compound balance weave belts:

- Small Product Conveyance

The close meshing and balanced spiral design of compound balance weave belts make them ideal for conveying small and delicate products without the risk of falling through the belt.

- Uniform Heat Transfer

These belts provide a uniform heat transfer across the entire surface due to their high density and smooth carrying surface. This is particularly beneficial in applications such as baking and heat treatment.

- High Tensile Strength

The compound structure, with multiple spirals and cross rods per pitch, contributes to higher tensile strength compared to other types of conveyor belts. This makes them suitable for handling heavy loads.

- Versatility in Applications

Compound balance weave belts find application in a wide range of industries, including the Heat Treat Industry for fasteners or powders, as well as baking bands in the Food Industry for products like tortillas, cookies, and crackers.

- Durable and Long Service Life

The unique construction and high-quality materials used in compound balance weave belts contribute to their durability and long service life, even in demanding industrial environments.

.jpg)