PRODUCTSSTAINLESS-STEEL-CONVEYOR-BELT

Featured products

Contact Us

Quenching is a critical heat treatment process involving rapid cooling of heated metals to achieve superior mechanical properties and increased hardness. Our specialized conveyor belts are engineered to withstand the extreme conditions of continuous hardening ovens up to 1200°C.

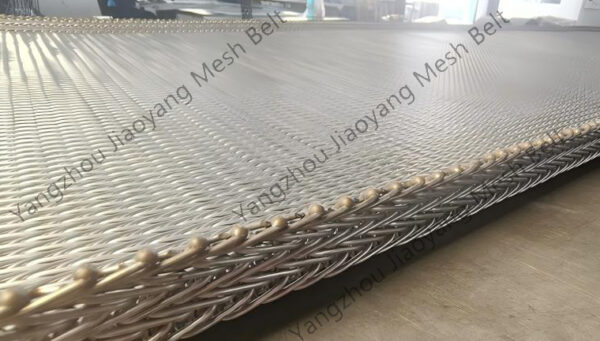

High-temperature resistant belt in industrial quenching application

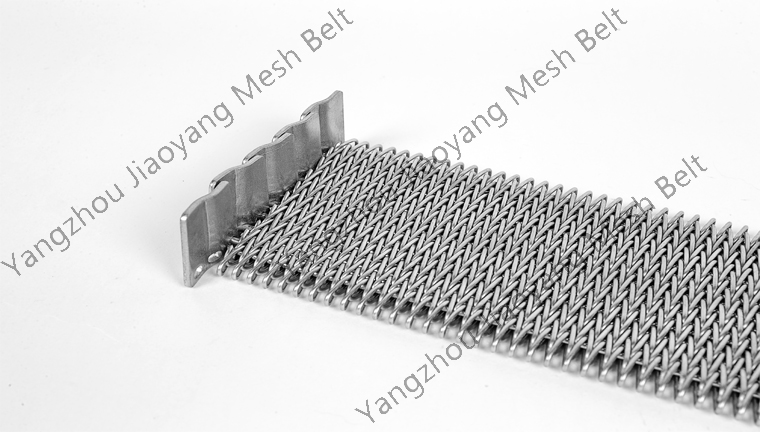

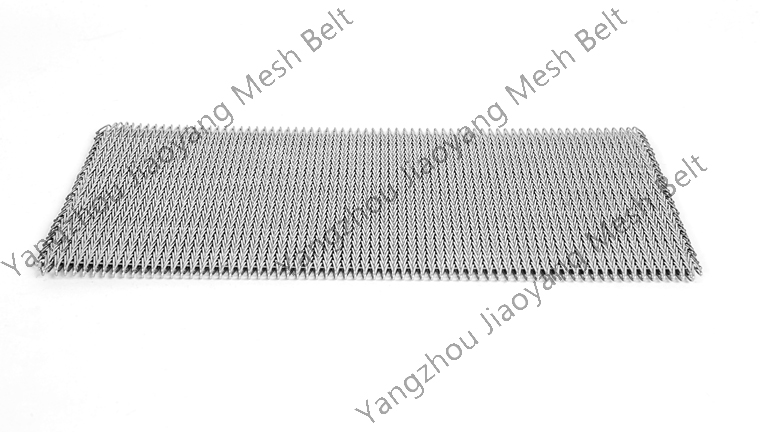

Tight “V” pattern with baffles for optimal material retention

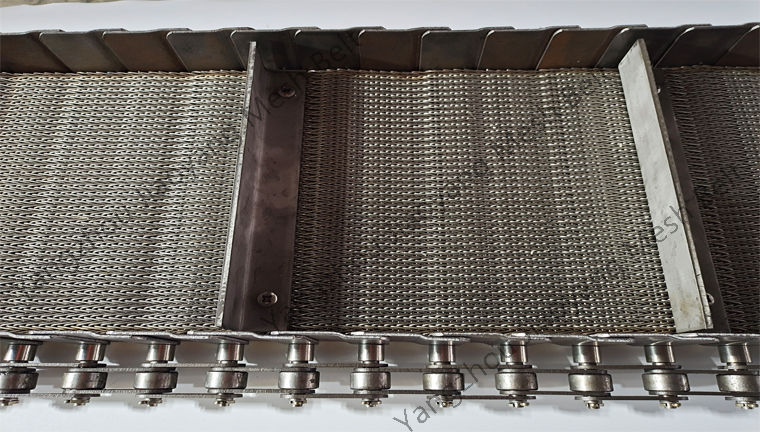

Chain-reinforced edges for enhanced durability

Precision direct edge welding technology

Edge turn-up design for improved stability

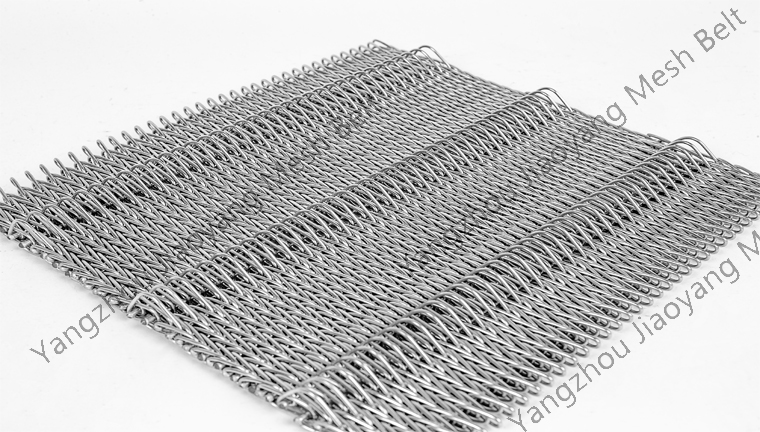

Compound Balanced Weave Conveyor Belt: Also known as Chevron Conveyor Belt. This specialized metal mesh belt features a unique “herringbone” pattern woven from left and right spiral wires. Its robust structure provides exceptional strength, temperature resistance, and stability – ideal for demanding quenching applications.

Available Materials

304 Stainless Steel

Standard corrosion resistance for general industrial use

314 Stainless Steel

Enhanced heat resistance for continuous high-temperature applications

316L Stainless Steel

Superior chemical resistance for harsh environments

Industrial Quenching Applications

Automotive Manufacturing

- Gearbox gear quenching

- Engine crankshaft hardening

- Bearing race heat treatment

- Transmission components

Tool Production

- Drill bit/milling cutter HSS quenching

- Blade edge hardening

- Mold surface strengthening

- Cutting tool manufacturing

Mechanical Components

- Hydraulic rod quenching

- Gear shaft heat treatment

- Mining machinery wear parts

- Axle components

Aerospace & Defense

- Turbine blade heat treatment

- Landing gear component hardening

- Armor plate quenching

- Special equipment wear treatment

Engineered for Extreme Quenching Environments

Our metal-hardening conveyor belts deliver unmatched reliability in continuous furnace operations

Material Solutions

Our metal-hardening conveyor belts utilize:

- AISI 314/310 stainless steel for standard quenching (up to 1150°C)

- Inconel 601 alloy for extreme temperature processes (1300°C+)

- Specialized weaving techniques to prevent thermal expansion issues

- Proprietary designs to eliminate cracking from rapid thermal cycling