NEWSNEWS

Featured products

Contact Us

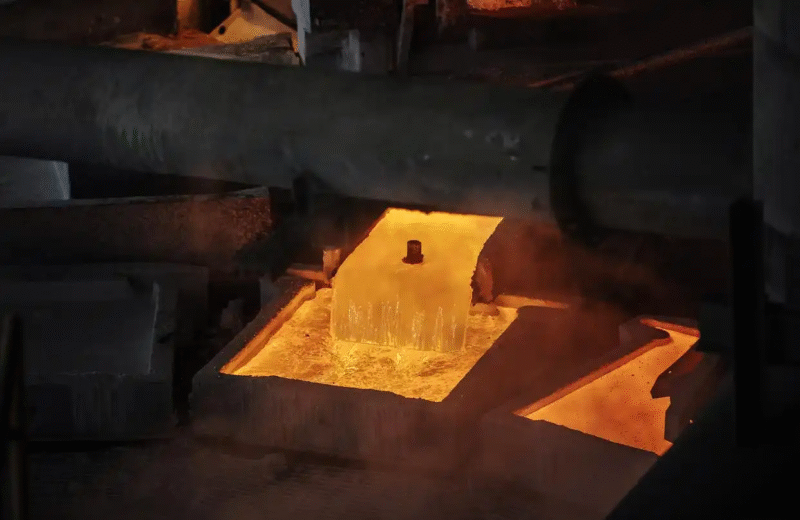

Quenching

2018-09-091. What is quenching?

Quenching of steel is a heat treatment process in which the steel is heated to a temperature above the critical temperature Ac3 (hypoeutectoid steel) or Ac1 (hypereutectoid steel), kept warm for a period of time, so that it is fully or partially austenitized, and then rapidly cooled to below Ms (or isothermally near Ms) at a cooling rate greater than the critical cooling rate for martensite (or bainite) transformation. The solid solution treatment of materials such as aluminum alloys, copper alloys, titanium alloys, and tempered glass, or the heat treatment process with a rapid cooling process is usually called quenching.

2. Purpose of quenching:

1) Improve the mechanical properties of metal products or parts. For example: improve the hardness and wear resistance of tools, bearings, etc., improve the elastic limit of springs, improve the comprehensive mechanical properties of shaft parts, etc.

2) Improve the material properties or chemical properties of certain special steels. For example, improve the corrosion resistance of stainless steel, increase the permanent magnetism of magnetic steel, etc.

During quenching and cooling, in addition to the reasonable selection of quenching media, the correct quenching method is also required. Commonly used quenching methods include single-liquid quenching, double-liquid quenching, graded quenching, isothermal quenching, local quenching, etc.

3. Steel workpieces have the following characteristics after quenching:

① Unbalanced (i.e. unstable) structures such as martensite, bainite, and residual austenite are obtained.

② There is a large internal stress.

③ The mechanical properties cannot meet the requirements. Therefore, steel workpieces generally need to be returned after quenching.