NEWSNEWS

Featured products

Contact Us

Improving Material Impression Marks: Conveyor Belts Starting from the “Wire”

2025-12-20To avoid scratches on the surface of workpieces, JiaoYang is sharing a precise process that combines efficiency and durability: flattened round wire.

Traditional conveyor belts are usually woven with metal wires of a circular cross-section. The surface flatness of these belts is limited, easily leading to vibration and slippage during material transport, which is particularly detrimental to precision parts or thin materials.

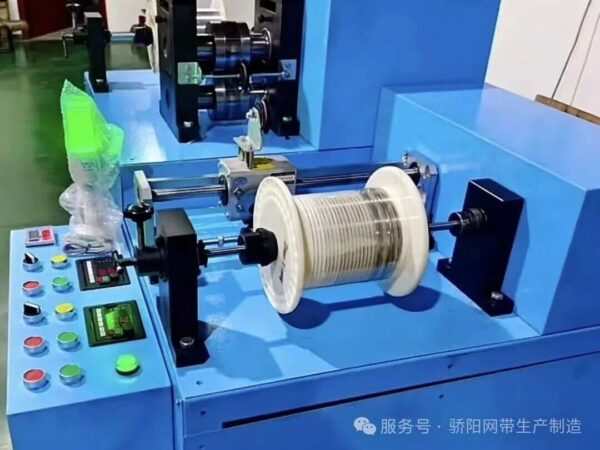

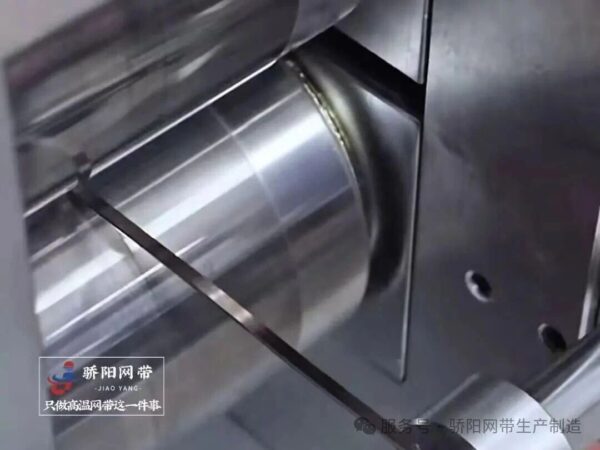

The flattened round wire process used by JiaoYang involves using specialized equipment to flatten the round metal wires into a flat shape, and then weaving the conveyor belt with these flattened wires.

During the flattening process, JiaoYang precisely calculates and controls the pressure, temperature, and speed to ensure that the performance of the metal wire is not compromised while achieving the required flatness.

Increased Contact Area, Improved Conveying Stability

The flattened metal wires have a significantly larger contact area with the material compared to round wires. This makes it less likely for the material to slide or roll during conveying, making it particularly suitable for inclined conveying and the transport of small items.

Reduced Material Jamming, Lower Maintenance Costs

Traditional round-wire woven metal mesh belts are prone to small materials getting stuck, which can affect equipment operation over time. Flat-wire woven mesh belts have a flatter surface and smaller gaps, significantly reducing material jamming problems.

Enhanced Belt Strength, Extended Service Life

The metal wires, scientifically flattened by advanced technology, have a changed cross-sectional shape that alters the stress distribution. With the same amount of material, they provide better resistance to bending and deformation, increasing the strength and durability of the mesh belt.

Improved Cleaning Performance, Meeting Hygiene Requirements

In industries with strict equipment cleaning requirements, the flat surface of the flat-wire mesh belt is easier to clean, leaving no dead corners.

Main Application Areas of Flat Wire Mesh Technology:

Food Processing

Used for conveying food products, the flat surface prevents product damage during processes such as cleaning and sorting, drying and dehydration, frying and cooling, baking and grilling, etc.

Automotive Industry

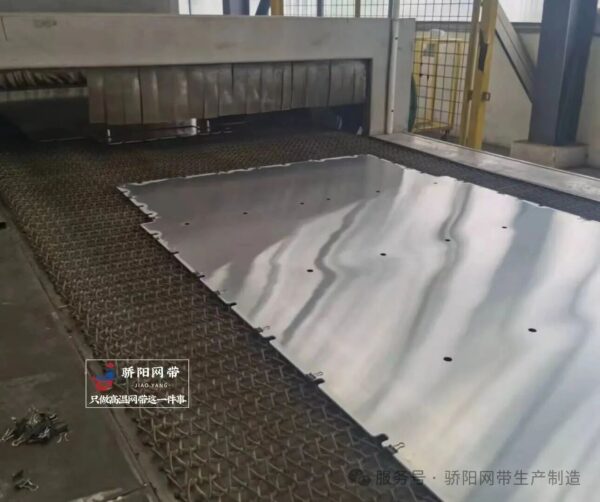

Used in processes such as automotive painting and brazing of automotive water-cooled and direct-cooled plates.

Glass Products

Provides stable conveyance of glass bottles and containers, reducing collision damage caused by rolling: used in glass forming and annealing, decorating or printing processes, etc.

Packaging and Logistics

Improves the efficiency of conveying cartons and packages, reducing jamming and downtime: used in warehousing and sorting centers, bottle and can packaging lines, agricultural product packaging and sorting, airport baggage handling, etc.