NEWSNEWS

Featured products

Contact Us

Common processes, material selection, and usage precautions for brazing furnace mesh belts

2025-12-0801. Material Selection

Jiaoyang conveyor belts are made from carefully selected 314 stainless steel, which maintains excellent mechanical properties and oxidation resistance even at high temperatures, effectively reducing hydrogen embrittlement. For the aluminum brazing industry, where temperatures do not exceed 800℃, Jiaoyang uses 316L stainless steel.

Jiaoyang recommends: For customers with sufficient budgets, relatively high furnace temperatures, and strict processing requirements, 2035 and 330 stainless steel can be considered to further improve the strength and corrosion resistance of the conveyor belt, ensuring stable operation and increasing production efficiency.

02. Process Optimization

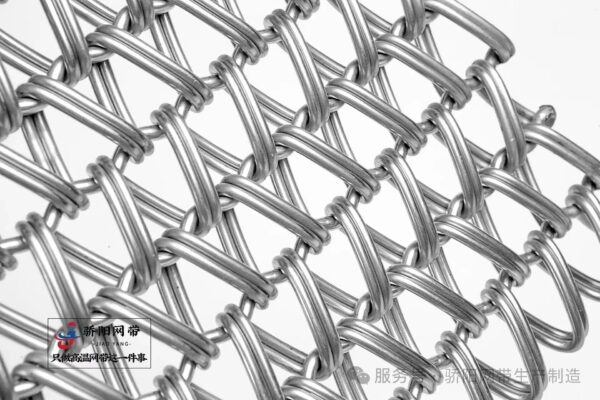

Jiaoyang’s meticulously crafted double-strand spiral structure design gives the high-temperature conveyor belt high tensile strength and load-bearing capacity. **The edges can be raised/raised to prevent material slippage, improving the conveyor belt’s load-bearing capacity and operational stability.

Jiaoyang’s brazing furnace conveyor belt, designed with spiral strips and woven wires in the same direction, is lightweight, has good air permeability, and reduces energy consumption while maintaining a large mesh size.

Jiaoyang employs a double-wound balanced structure combined with crankshaft embossing technology. This results in precise positioning and reduces the risk of deviation, but it is not suitable for customers with high load-bearing requirements.

03. Standardized Use

Damage to the brazing furnace mesh belt is often closely related to improper operation.

1. Ensure even distribution of workpieces during loading and control the load per load within the mesh belt’s bearing capacity.

2. Lay graphite or stainless steel pads on the mesh belt to prevent direct contact between the solder and the belt, thus avoiding chemical reactions.

3. Keep the furnace interior clean to prevent impurities from accumulating and causing mechanical friction. Repair any minor damage immediately.

4. Regular inspection, cleaning, and maintenance of the brazing furnace mesh belt are crucial steps in extending its service life.