PRODUCTSSTAINLESS-STEEL-CONVEYOR-BELT

Featured products

Contact Us

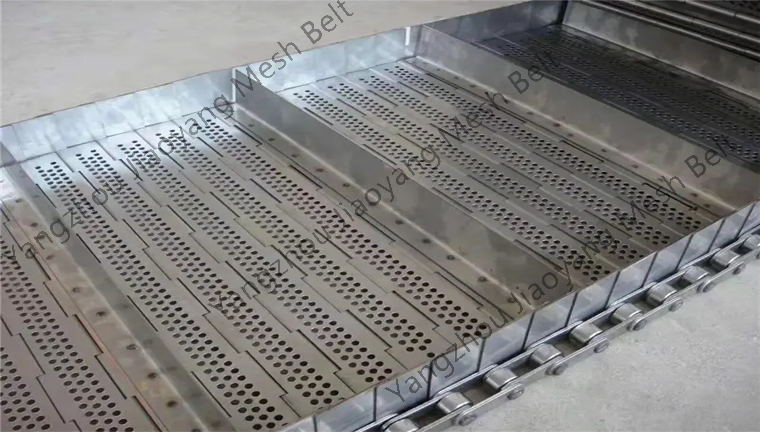

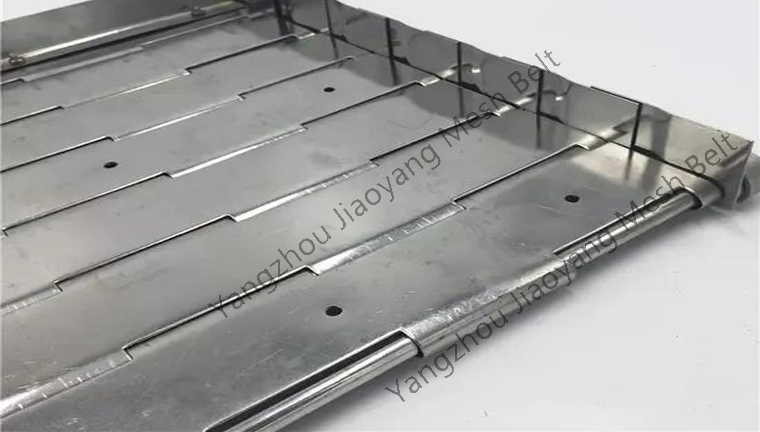

Plate Link Conveyor Belt

Plate conveyor belts are composed of hinged slats with or without holes. Hinge ……

Plate conveyor belts are composed of hinged slats with or without holes. Hinge plate belts have side and cross plates with various height and thickness combinations to meet the needs of different customers. The chains at both ends can be fixed with cotter pins or washers for easy removal and maintenance.

Key Advantages:

- Multiple plate configurations (solid/perforated)

- Customizable height and thickness options

- Secure chain fixation with cotter pins/washers

- Easy maintenance and part replacement

- Heavy-duty construction for demanding applications

Key Applications

- Food Industry: In the baking workshop, the chain plate mesh belt conveyor carries freshly baked bread and pastries. On the meat processing line, it can easily cope with multiple processes such as cutting, pickling, and smoking. In the field of fruit and vegetable processing, the chain plate mesh belt conveyor is used for washing, peeling, slicing and subsequent packaging processes with its stable conveying speed and precise positioning.

- Pharmaceutical Manufacturing: In the pharmaceutical manufacturing industry, chain plate conveyor belts are used for precise sorting, packaging and handling of tablets.

- Chemical Industry: Mesh belts are also commonly used in the chemical industry to meet the needs of continuous material transportation. Its compact structure, high stability and high conveying efficiency make it play an important role in chemical production. Electronic

- Industry: In the assembly, testing and packaging of electronic components.

- Automobile Manufacturing: On the automobile parts assembly line.

Tags: