NEWSNEWS

Featured products

Contact Us

Heat treatment mesh belt for needle making industry

2025-05-06Bosses in the needle making industry, embroidery needles are as thin as cow hair. This kind of workpiece is prone to leakage and jamming during transportation, so the fineness of the high-temperature mesh belt is very important. The metal mesh belt that Jiaoyang Mesh Belt Workshop is shipping takes into account the specifications, dimensions and materials of the needle parts to ensure smooth mesh belt transportation.

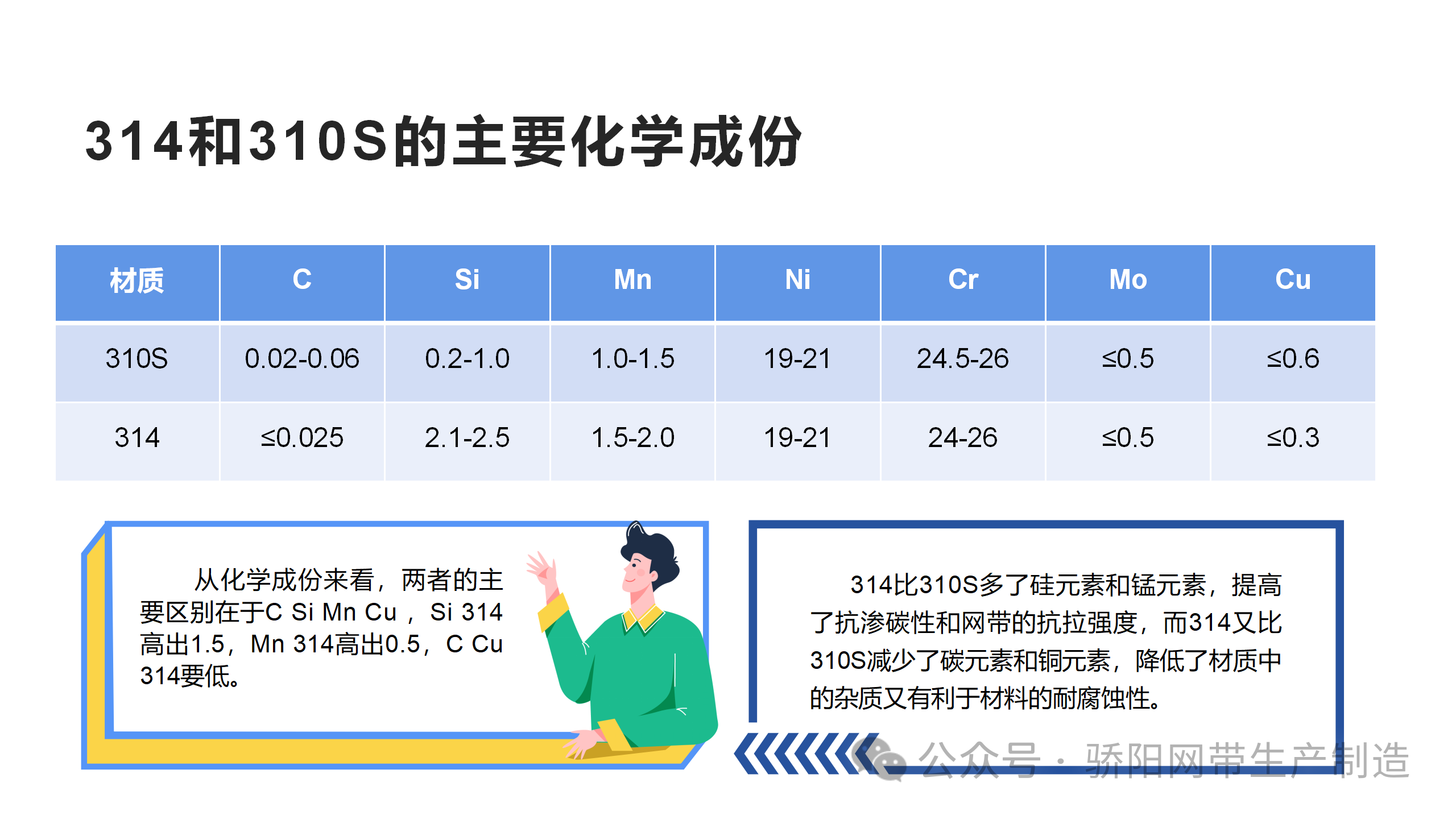

Considering the processing requirements of embroidery needles and the thin and small size of workpieces, Jiaoyang Mesh Belt strictly selects sus314 stainless steel wire that meets international standards. It can withstand temperatures above 1000 degrees and has excellent tensile strength in high temperature environments. Because this material contains silicon, it also has strong antioxidant properties.

Considering that the fine-pointed embroidery needle is difficult to hold steady by hand, the Jiaoyang mesh belt adopts a tight herringbone weaving process, the mesh surface is flat and has no gaps.

Ensure that the embroidery needles are stable and do not deviate during transportation, and there will be no leakage or jamming of materials.

With many years of experience in mesh belt R&D and production, Jiaoyang has customized this high-temperature mesh belt for customers. The wire diameter is 0.8mm, the threading is 1.2mm, and the width is only 5.5cm. It is specially designed for the needle-making industry, with exquisite craftsmanship, smooth surface and uniform mesh. The high-temperature mesh belt has a moderate thickness to ensure its compression resistance while the mesh belt is not stiff.