NEWSNEWS

Featured products

Contact Us

Are there hidden tricks to high-temperature conveyor belt packaging? How to choose the right one?

2025-11-01Customers who buy conveyor belts, have you noticed that even within the same industry, with similar equipment, and using high-temperature conveyor belts for tunnel furnaces, the packaging and shipping methods can differ? So what are the main packaging and shipping methods for conveyor belts? What are the differences between them? How do you choose the right packaging method for your conveyor belt? Jiaoyang will discuss this with you today!

Packaging methods and main categories

Currently, there are three main types of high-temperature mesh belt packaging on the market: large roll packaging, small roll packaging, and folded packaging. What are the differences between them?

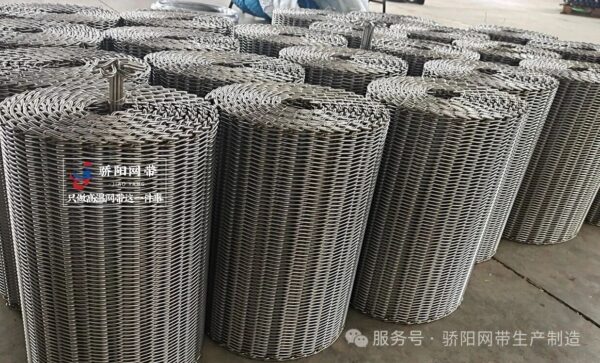

Large roll packaging

Large roll packaging is typically suitable for customers who want to replace the entire conveyor belt and have large loading and unloading equipment. This packaging method maintains the integrity of the conveyor belt and avoids unnecessary joints, but it requires a large loading and unloading area and professional hoisting equipment.

If you have ample space and a professional installation team, large roll packaging is undoubtedly the ideal choice. It not only maintains the integrity of the conveyor belt but also saves installation time and improves work efficiency.

The small roll packaging

The small roll packaging uses a split-roll design, which facilitates manual handling and is especially suitable for workshop environments with limited space. Although the conveyor belt has joints, it greatly reduces the requirements for loading and unloading equipment.

If you have a large workshop but lack professional installation personnel, small roll packaging may be more suitable for your needs. Each roll is of moderate weight, making it easy for ordinary employees to handle and install using simple tools, reducing reliance on specialized equipment.

Folding packaging

Folding packaging involves folding the conveyor belt into a certain shape according to a certain pattern, which effectively saves transportation space and reduces transportation costs, but requires more manpower to unfold and adjust during installation.

When faced with limited on-site operating space and the inability to deploy large equipment, the advantages of folding packaging become apparent. It can complete unloading and installation within narrow passages and limited spaces, solving many problems in the renovation of old factory areas.

At Jiaoyang, we firmly believe that true service lies in the details. Jiaoyang’s professional consultants will thoroughly understand your site conditions, equipment, and staffing, and based on their extensive industry experience, recommend the most suitable packaging and shipping solutions for you.

For special working conditions, Jiaoyang can dispatch professional technicians to provide on-site guidance for the installation of the conveyor belt.

Have you ever experienced installation problems due to improper packaging? Feel free to share your experience in the comments section; perhaps our professional advice can solve your problem.