MaterialMATERIAL

Featured products

Contact Us

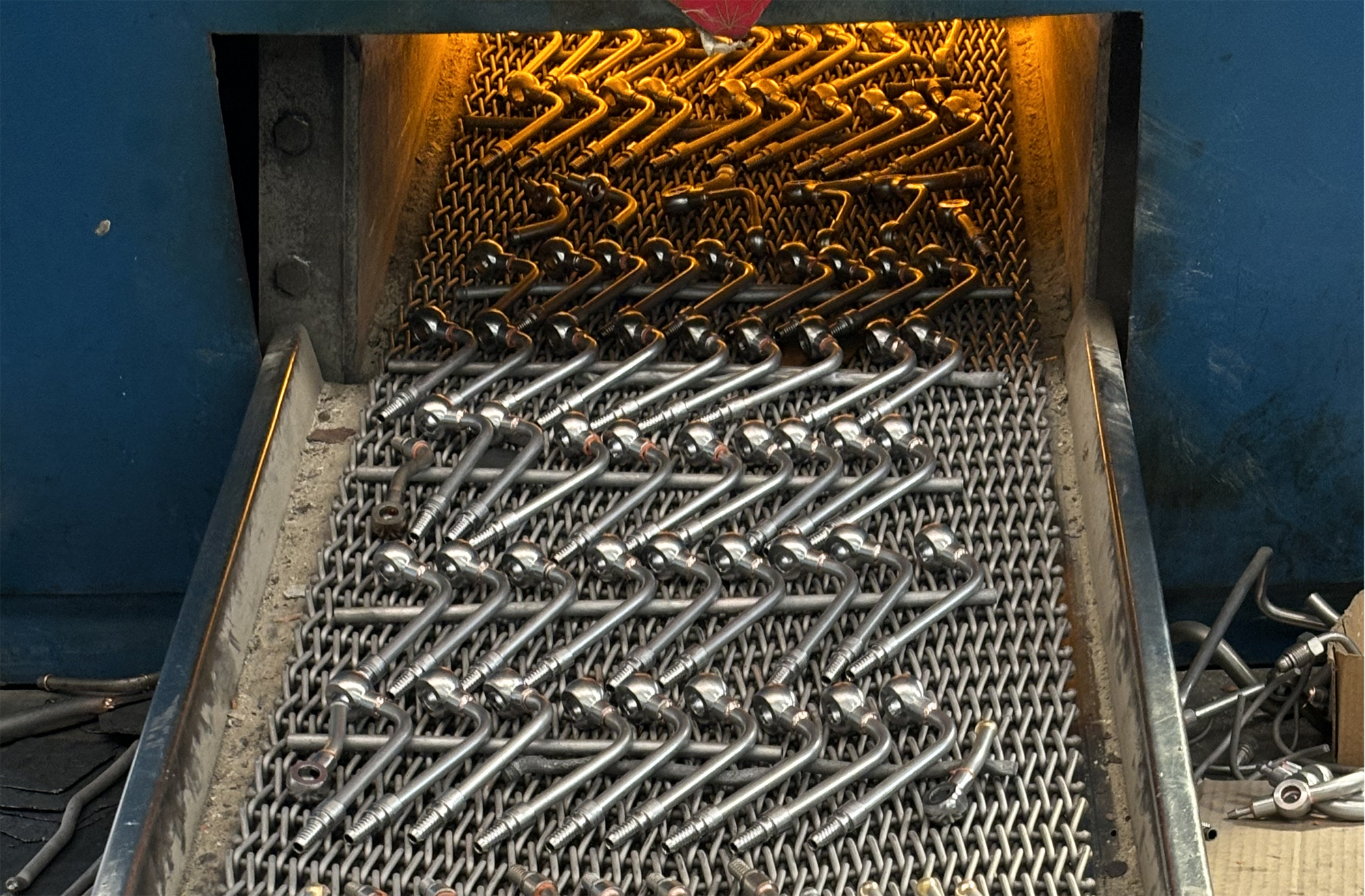

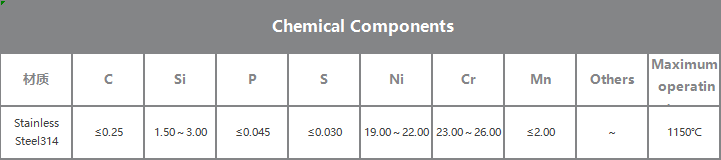

It belongs to austenitic stainless steel (300 series), which is a high-chromium, high-silicon high-temperature resistant special stainless steel designed for extremely high temperature oxidation and corrosive resistance environments.There are many types of stainless steel 314 mesh belts, such as balanced mesh belts, double-strand balanced mesh belts, herringbone mesh belts, Great Wall mesh belts, Type B mesh belts, etc.

Powder metallurgy sintering furnace mesh belt

Brazing furnace mesh belt

Heat treatment furnace mesh belt

Oil-bearing sintered mesh belt

High temperature resistant baking furnace mesh belt

Application scenarios

1. High-temperature industrial furnaces and heat treatment equipment

Scenario:

Industrial furnace components: annealing furnaces, carburizing furnaces, sintering furnaces, furnace tubes, furnace bottom plates, brackets, conveyor belts.

Glass annealing furnaces: support structures in high-temperature zones, heat-resistant fixtures.

2. Petrochemical and energy industries

Scenario:

Cracking furnaces and reforming units: high-temperature furnace tubes (such as ethylene cracking furnaces), converter linings.

Coal/gas-fired boilers: superheaters, reheater pipes, burner nozzles (resistance to high-temperature corrosion containing vanadium/sulfur).

3. Metallurgy and non-ferrous metal industries

Scenario:

Copper/aluminum smelting furnaces: furnace linings, stirrers, casting molds.

Alloy heat treatment equipment: trays and baskets for high-temperature brazing furnaces (resistance to molten brazing flux corrosion).

4. Waste incineration and chemical waste treatment

Scenario:

Combustion chamber of waste incinerator: high-temperature zone furnace walls, fly ash treatment equipment (resistance to corrosive gases such as HCl and Cl₂).

Chemical waste incinerator: high-temperature components for handling sulfur and halogen compounds.

5. Ceramic and refractory industry

Scenario:

Ceramic sintering kiln: push plate, kiln car track, high-temperature shelf.

Refractory testing equipment: sample holder in high-temperature furnace (resistant to erosion by molten refractory materials).

6. Nuclear industry and special high-temperature equipment

Scenario:

Nuclear reactor auxiliary system: heat exchanger components of high-temperature gas-cooled reactor (non-core radiation area).

Experimental high-temperature furnace: ultra-high temperature experimental device of scientific research institutions (such as atmosphere furnace above 1200℃).